Features

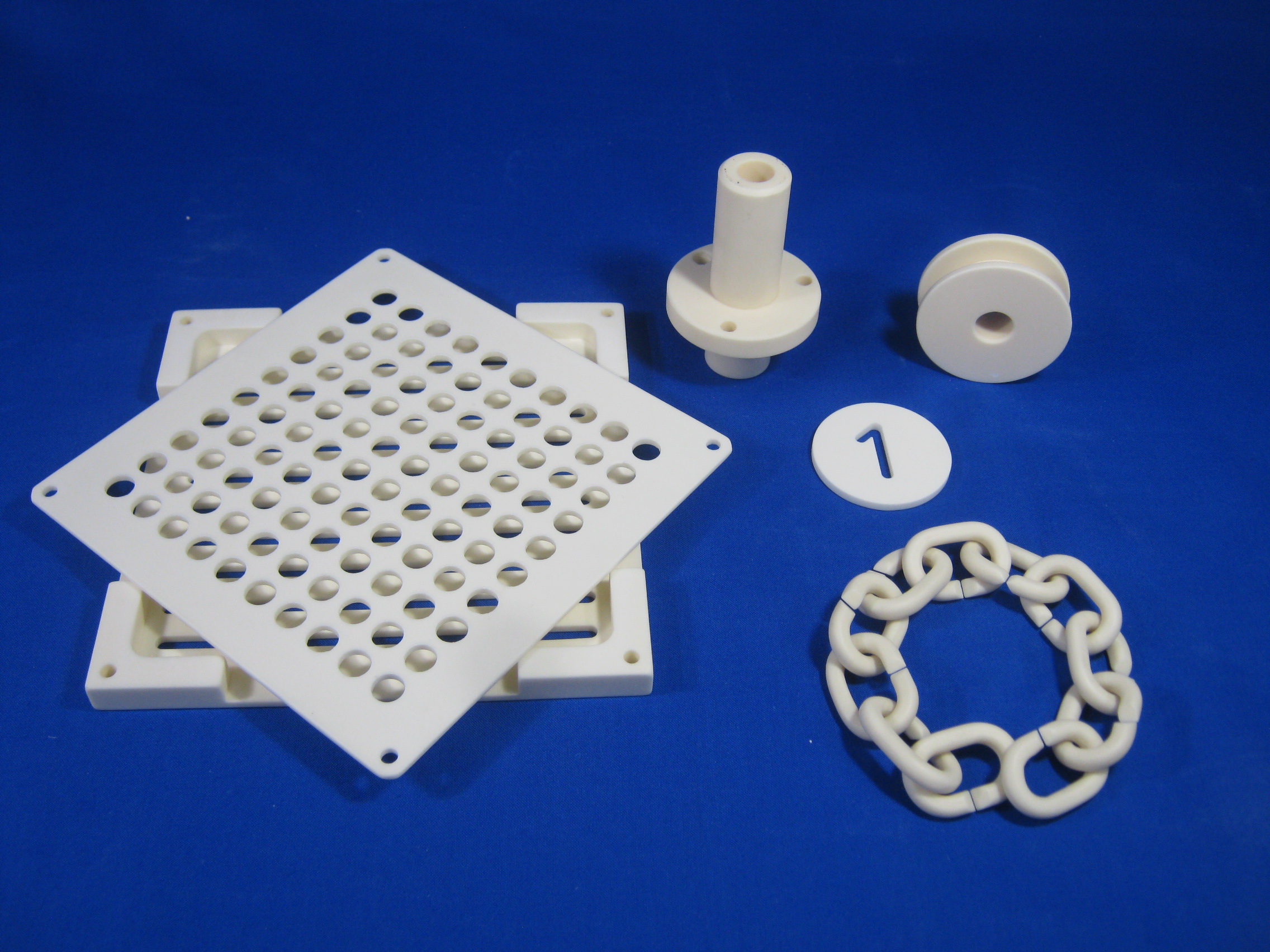

CIP (Rubber Press) Products are highly and homogeneously condensed non-porous products because they are made under the ultra-high pressure in all the directions.

Rubber molds, which are suitable for smaller quantity production but less expensive, are used in the CIP manufacturing process.

Product group : FA-PS99

Our FA-PS99 is the slip casting products with no less than 99.5% pure alumina powder formed under high pressure and sintered at ultra-high temperature achieving high level of intensity.

Superior in non-wetting behavior and wet corrosion resistance against fused slag base or fused metal.

As well as in thermal conduction, refractoriness and wear resistance.

Product group : FA-PS96

Our FA-PS99 is the slip casting products with 96% pure alumina powder formed under high pressure and sintered at ultra-high temperature, in the same way as FA-PS99, achieving high level of intensity.

Superior in corrosion resistance and thermal shock resistance.

Both features and prices range between those of FA-PS99 and FA-PS92.

Product group : FA-PS92

Our FA-PS92 is the slip casting products with 92% pure alumina powder formed under high pressure and sintered at ultra-high temperature, in the same way as FA-PS99, achieving lower cost of production.

Widely used in high intensity insulation parts for heating.

Table of Physical Properties

| Product group | FA-PS99 | FA-PS96 | FA-PS92 | |

|---|---|---|---|---|

| Materials | Alumina 99.5% | Alumina 96% | Alumina 92% | |

| Appearance | Non-porous | |||

|

Chemical Ingredients (Wt%) |

Al2O3 | 99.5 | 96 | 92 |

| SiO2 | 0.05 | 2.3 | 5.5 | |

| MgO | 0.1 | 0.7 | 1.0 | |

| Na2O3 | 0.1 | 0.3 | 0.3 | |

| CaO | – | 0.6 | 0.7 | |

| Fe2O3 | 0.02 | 0.02 | 0.05 | |

|

Specific Gravity (g/cm3) |

3.9 | 3.6 | 3.5 | |

|

Water-absorption Rate (%) |

0.0 | |||

|

Thermal Conductivity (W/mk) |

36 | 32 | 17 | |

|

Flexural Strength (MPa) |

300 | 300 | 250 | |

|

Refractoriness (℃) |

1800 | 1700 | 1600 | |

|

Impedance (20℃,Ωcm) |

No less than 1013 | |||

|

Thermal Shock Resistance (℃/hr) |

300 | |||

| Color Appearance | Ivory | White | ||

| Intended Application |

Chemistry Laboratory Instruments Metal Melting Crucibles Wear Resistant Parts Protection Tube |

Sintering Container for Electronic Parts Wear Resistant Parts Pipe Insulation |

Insulation Parts Ceramic Insulators for Electric Heater |

|

Variety of Our Products and Measurement Table (FA-PS99 Alumina 99.5% Non-porous)

We will produce the item in sizes other than those shown below for a minimum order quantity of 5.

Inquiry or Estimation Request is Free of Charge.

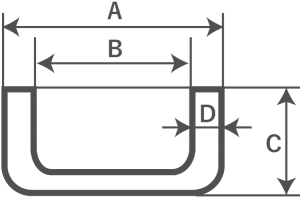

Sagger (Boat / Rod)

| Catalog Number | Outer Length(A) | Inner Length(B) | Height(C) | Wall Thickness(D) |

|---|---|---|---|---|

| □65 × 65h | 65 | 57 | 65 | 4 |

| □84 × 45h | 84 | 78 | 45 | 3 |

| □112 × 65h | 112 | 100 | 65 | 6 |

| □142 × 45h | 142 | 130 | 45 | 6 |

| □158 × 19.5h | 158 | 146 | 19.5 | 6 |

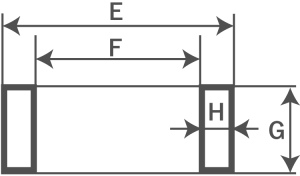

Frame

| Catalog Number | Outer Length(E) | Inner Length(F) | Height(G) | Wall Thickness(H) |

|---|---|---|---|---|

| □65 × 25h | 65 | 57 | 25 | 4 |

| □113 × 50h | 113 | 102 | 50 | 5.5 |

| □120 × 40h | 120 | 109 | 40 | 5.5 |

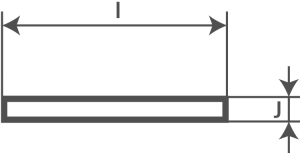

Plates (Setters / Lids)

| Catalog Number | Outer Length(I) | Height(J) |

|---|---|---|

| □65 × 4t | 65 | 4 |

| □88 × 4t | 88 | 4 |

| □115 × 4t | 115 | 4 |

| □123 × 5t | 123 | 5 |

| □145 × 5t | 145 | 5 |

| □154 × 5t | 154 | 5 |

| □162 × 5t | 162 | 5 |

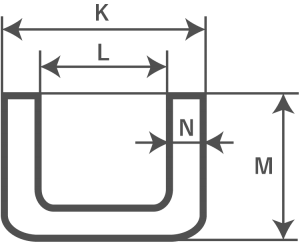

Crucibles

| Catalog Number | Outer Diameter(K) | Inner Diameter(L) | Height(M) | Wall Thickness(N) |

|---|---|---|---|---|

| Ø15 × 100h | 15 | 12 | 100 | 1.5 |

| Ø30 × 150h | 30 | 24 | 150 | 3 |

| Ø40 × 140h | 40 | 33 | 140 | 3.5 |

| Ø50 × 150h | 50 | 42 | 150 | 4 |

| Ø60 × 150h | 60 | 52 | 150 | 4 |

| Ø80 × 150h | 80 | 71 | 140 | 4.5 |

| Ø100 × 150h | 100 | 91 | 150 | 4.5 |

| Ø126 × 230h | 126 | 116 | 230 | 5 |

| Ø145 × 230h | 145 | 135 | 230 | 5 |

| Ø205 × 325h | 205 | 185 | 325 | 10 |