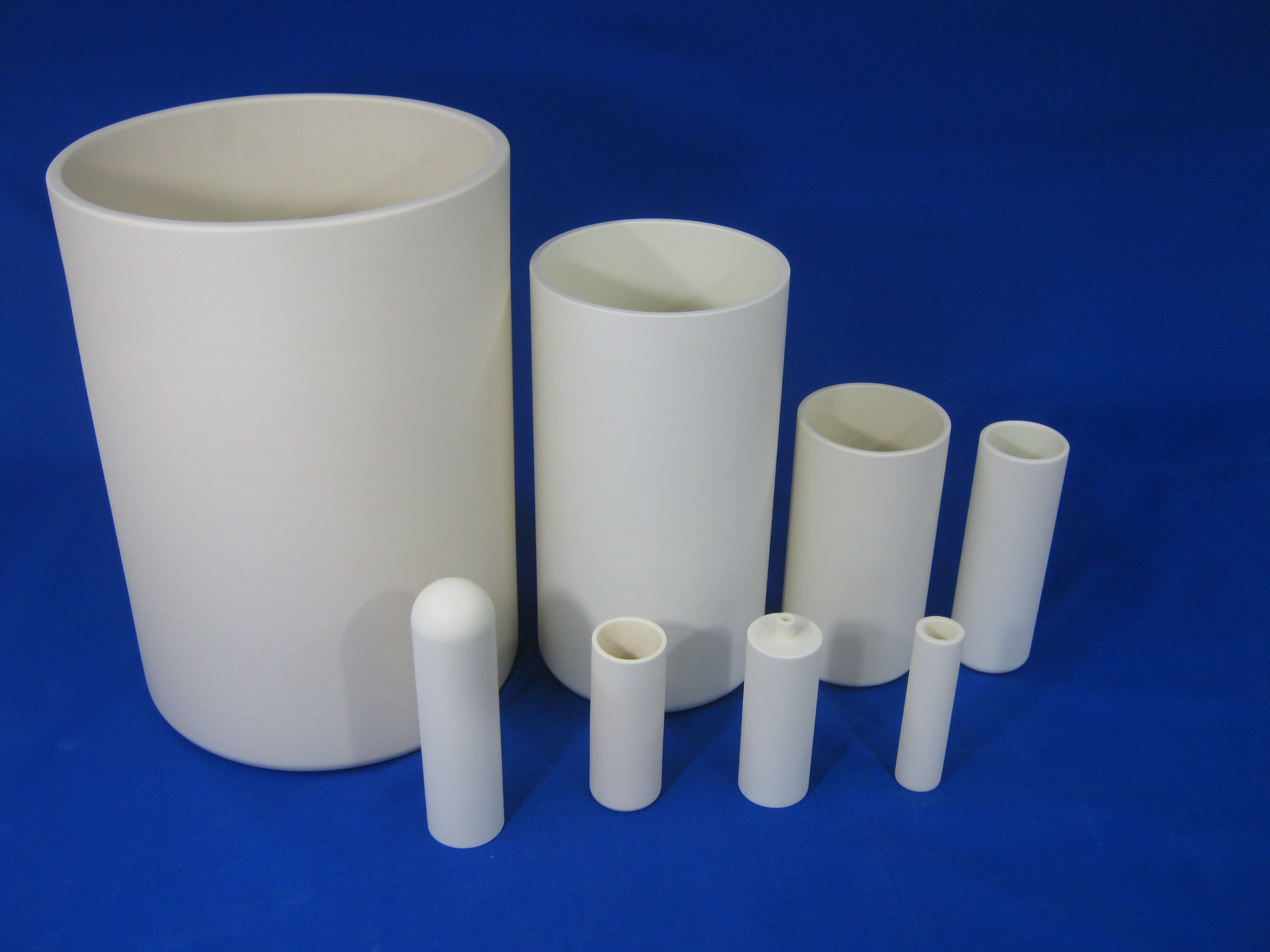

Features

CIP (Rubber Press) Products are highly and homogeneously condensed non-porous products because they are made under the ultra-high pressure in all the directions.

Rubber molds, which are suitable for smaller quantity production but less expensive, are used in the CIP manufacturing process.

Magnesia CIP Products are

- Especially superior in non-wetting behavior and wet corrosion resistance against fused slag base or fused metal.

- Chemically inert and highly heat resistant.

- Superior in electrical conductivity in high temperature and high frequency range.

Owing to these features, Magnesia CIP Products are best suitable porcelain products as Sagger (Boat / Rod) for sintering electric parts.

As compared to our conventional production method, their thermal shock resistance have been significantly enhanced by controlling particle-size distribution of magnesia and by dispersing fine closed pore through the use of our special sintering technologies.

Owing to the feature of lead component, our magnesia setters have few pores of external crystal grain boundary, resulting in little lead infiltration. There is scarcely any lead infiltration into the setter which can be observed in alumina products.

Table of Physical Properties

| Product group | FM-PS | FM-PSC | |

|---|---|---|---|

| Materials | Magnesia 99% | ||

| Appearance | Non-porous | ||

|

Chemical Ingredients (Wt%) |

MgO | 98.4 | 99 |

| Al2O3 | 1.0 | 0.5 | |

| ZrO2 | 0.2 | 0.02 | |

| SiO2 | 0.1 | 0.2 | |

| CaO | 0.3 | 0.3 | |

| Fe2O3 | 0.1 | 0.08 | |

|

Specific Gravity (kg/cm3) |

3.3 | ||

|

Water-absorption Rate (%) |

0.0 | ||

|

Thermal Conductivity (W/mk) |

71 | ||

|

Flexural Strength (MPa) |

150 | ||

| Refractoriness (℃) |

1800 | ||

| Impedance (20℃,Ωcm) |

No less than 1013 | No less than 1014 | |

| Thermal Shock Resistance (℃/hr) |

250 | 200 | |

| Color Appearance | Ivory | ||

| Intended Application |

Sintering Container for Electronic Parts Metal Melting Crucibles Protection Tube Pipe Insulation |

Chemistry Laboratory Instruments | |

Variety of Our Products and Measurement Table (FM-PS Magnesia 99% Non-porous)

We will produce the item in sizes other than those shown below for a minimum order quantity of 5.

Inquiry or Estimation Request is Free of Charge.

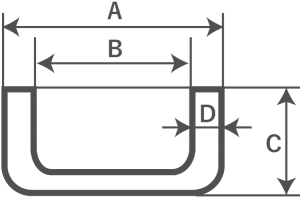

Sagger (Boat / Rod)

| Catalog Number | Outer Length(A) | Inner Length(B) | Height(C) | Wall Thickness(D) |

|---|---|---|---|---|

| □70 × 70h | 70 | 62 | 70 | 4 |

| □90 × 50h | 90 | 84 | 50 | 3 |

| □120 × 70h | 120 | 108 | 70 | 6 |

| □121 × 70h | 121 | 110 | 70 | 5.5 |

| □152 × 50h | 152 | 140 | 50 | 6 |

| □162 × 50h | 162 | 150 | 50 | 6 |

| □170 × 20h | 170 | 158 | 20 | 6 |

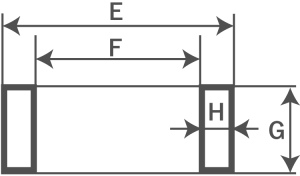

Frame

| Catalog Number | Outer Length(E) | Inner Length(F) | Height(G) | Wall Thickness(H) |

|---|---|---|---|---|

| □70 × 25h | 70 | 62 | 25 | 4 |

| □121 × 55h | 121 | 110 | 55 | 5.5 |

| □128 × 80h | 128 | 117 | 80 | 5.5 |

| □162 × 40h | 162 | 150 | 40 | 6 |

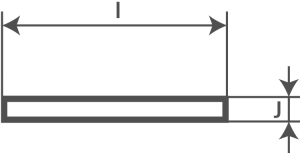

Plates (Setters / Lids)

| Catalog Number | Outer Length(I) | Height(J) |

|---|---|---|

| □70 × 4t | 70 | 4 |

| □94 × 5.7t | 94 | 5.7 |

| □124 × 4t | 124 | 4 |

| □132 × 5t | 132 | 5 |

| □156 × 5t | 156 | 5 |

| □166 × 5t | 166 | 5 |

| □174 × 5t | 174 | 5 |

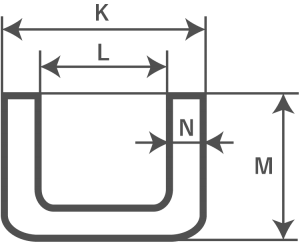

Crucibles

| Catalog Number | Outer Diameter(K) | Inner Diameter(L) | Height(M) | Wall Thickness(N) |

|---|---|---|---|---|

| Ø20 × 70h | 20 | 14 | 70 | 3 |

| Ø30 × 50h | 30 | 23 | 50 | 3.5 |

| Ø40 × 50h | 40 | 33 | 50 | 3.5 |

| Ø50 × 150h | 50 | 42 | 150 | 4 |

| Ø60 × 150h | 60 | 52 | 150 | 4 |

| Ø72 × 150h | 72 | 60 | 150 | 6 |

| Ø85 × 150h | 85 | 77 | 150 | 4 |

| Ø110 × 50h | 110 | 98 | 160 | 6 |

| Ø135 × 250h | 135 | 125 | 250 | 5 |

| Ø155 × 250h | 155 | 145 | 250 | 5 |

| Ø220 × 350h | 220 | 200 | 350 | 10 |