Features

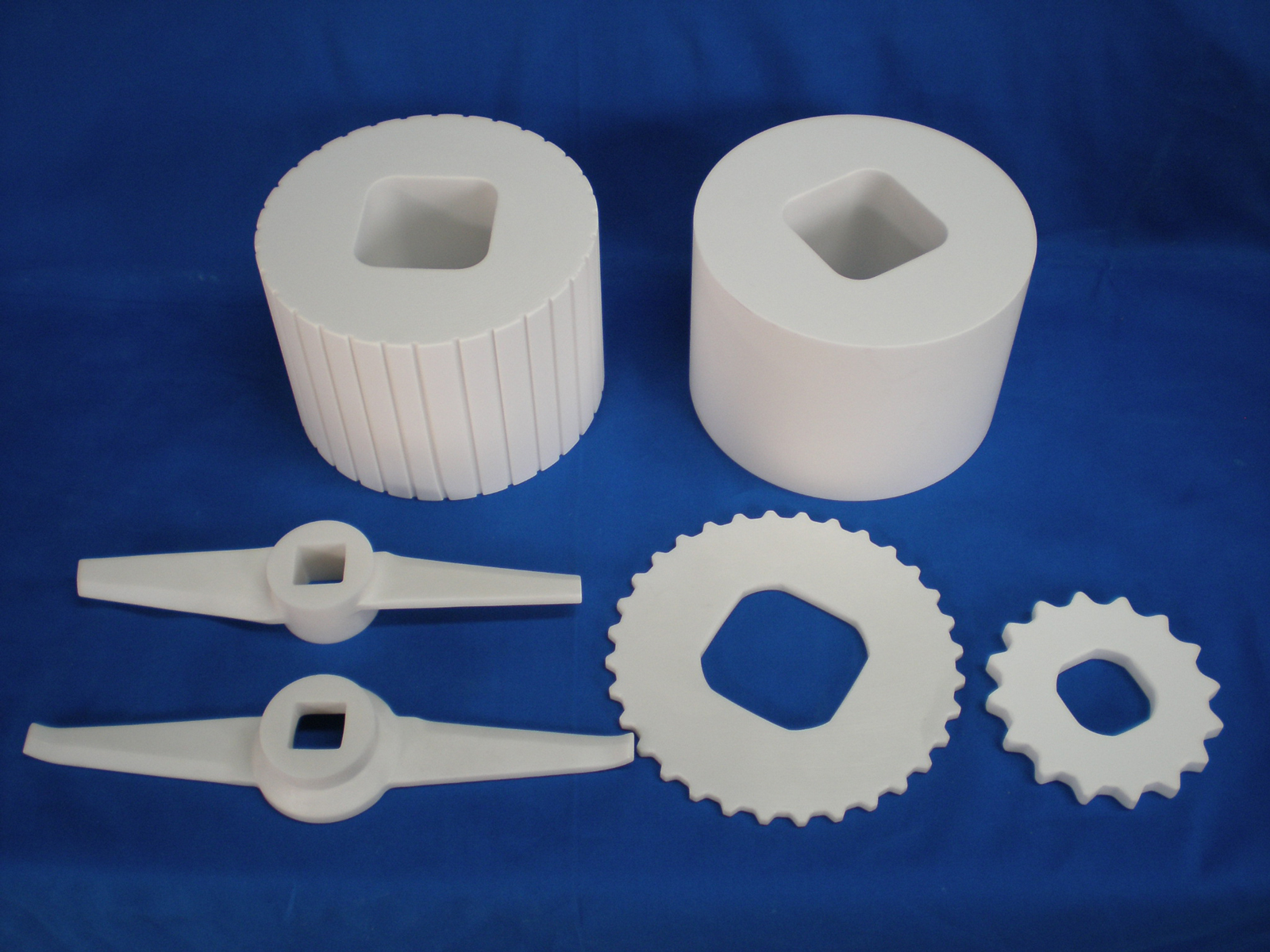

CIP (Rubber Press) Products are highly and homogeneously condensed non-porous products because they are made under the ultra-high pressure in all the directions.

Rubber molds, which are suitable for smaller quantity production but less expensive, are used in the CIP manufacturing process.

Product group : FZ-PSY

- Ceramics with high level of intensity and fracture toughness

- The most popular materials for wear resistant or shock resistant parts

Product group : FZ-PS8Y

- Having unique features which differs from that of alumina in response to metals

Table of Physical Properties FZ-PSY Series

| Product group | FZ-PS3Y | FZ-PS8Y | |

|---|---|---|---|

| Materials | Partially Stabilized Zirconia | Fully Stabilized Zirconia | |

| Appearance | Non-porous | ||

|

Chemical Ingredients (Wt%) |

ZrO2 | 94 | 86 |

| Y2O3 | 5.5 (3mol) | 14.0 (8mol) | |

| Al2O3 | 0.2 | 0.0 | |

|

Specific Gravity (g/cm3) |

6.0 | 5.8 | |

|

Water-absorption Rate (%) |

0.0 | 0.0 | |

|

Thermal Conductivity (W/mk) |

3 | 8 | |

|

Flexural Strength (MPa) |

1200 | 300 | |

|

Normal operating temperature (℃) |

1000 | 1400 | |

|

Impedance (20℃,Ωcm) |

1010~13 | – | |

|

Thermal Shock Resistance (℃/hr) |

300 | – | |

| Color Appearance | Milky White | ||

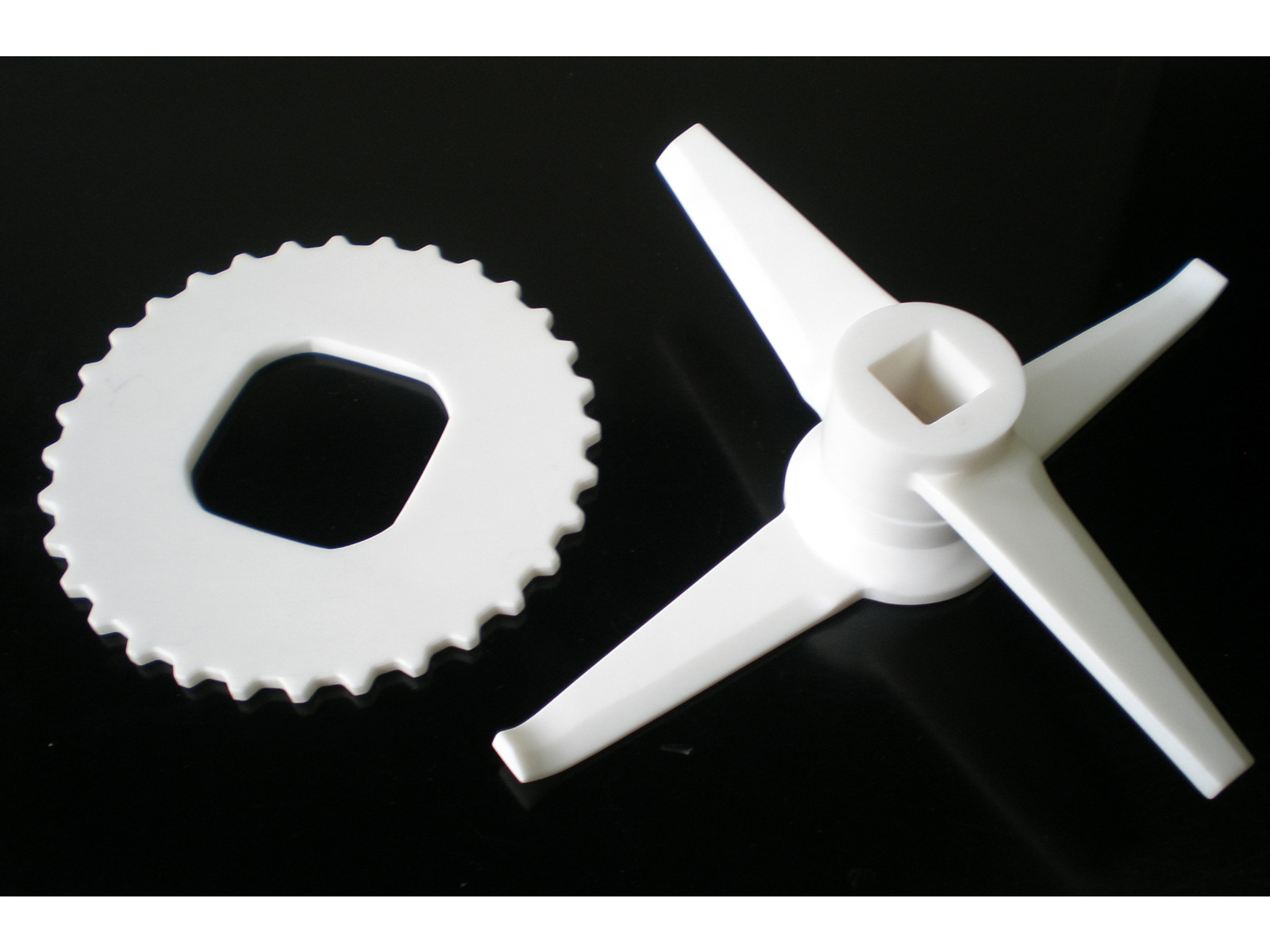

| Intended Application | Wear resistant parts(Nozzle, Ring and Bearing) Parts with characteristic feature of high-intensity and fracture-toughness Zirconia pot mills Screw / Stirring blades |

Jigs for sintering electronic parts(Corrosion resistant setter) Thermal insulation materials | |